Industry value

Driving innovations through research and expertise

Over the years, we have invested in facilities and talent that have made us the industry authority on the application of aramid materials to consistently improve our customers’ products. Here are the facts:

Knowledge and expertise

Scientifically proven, business relevant

At Teijin Aramid, our deep-rooted scientific expertise and commitment to R&D shape quality solutions. We use and share our knowledge in collaborative partnerships that create value for customers across a spectrum of sectors and use cases.

Sustainability

Closing the circularity loop

We celebrated a 50% rise in the intake of end-of-life aramid material in 2022, and in a R&D breakthrough, we became the first to produce aramid on an industrial scale from circular material. Years of research and trials resulted in a production run of Twaron® produced from recycled yarn in 2023.

R&D

Our research and development streams

We’ve organized our expertise to cover a variety of customer needs.

Technical account management

Our technical account managers personally advise our customers on the best technical solutions for their needs from our regional offices. They often work closely with higher-level, diverse services of our Research and Innovation Center in Arnhem.

- Advise on optimal aramid product selection and application

- Discuss customized solutions to fit unique requirements

- Troubleshoot technical challenges in product implementation and performance

Approver enabler process

We test materials on both primary and secondary properties. Secondary property testing refers to the performance of aramid applications in specific conditions, such as at extreme temperatures, certain levels of humidity, UV light or in sea water. This process ensures that, even when a product process undergoes adjustments, the performance and fit-for-purpose level of the aramid solution remains unaffected.

We are currently the only major aramid producer carrying out this type of testing in a systematic way.

Certification process support

Once aramid solution has been defined, we work with partners and customers to achieve qualification and certification standards for new aramid applications. This process is supported in an ongoing manner by our approver enabler process.

Quality guardianship

Our R&D team is the custodian of our quality standards. They scrutinize our products and processes to safeguard product quality. Our Research and Innovation Center staff design and set the standards of quality and supply these to our quality testing teams at production to ensure that the product ordered meets the precise specifications required by the customer.

Quality assurance

Resource library

Explore safety and quality assurance certificates that are in line with ISO quality standards. You can also find data about health and safety, eco-data sheets, and information about environmental impact at a corporate and product level.

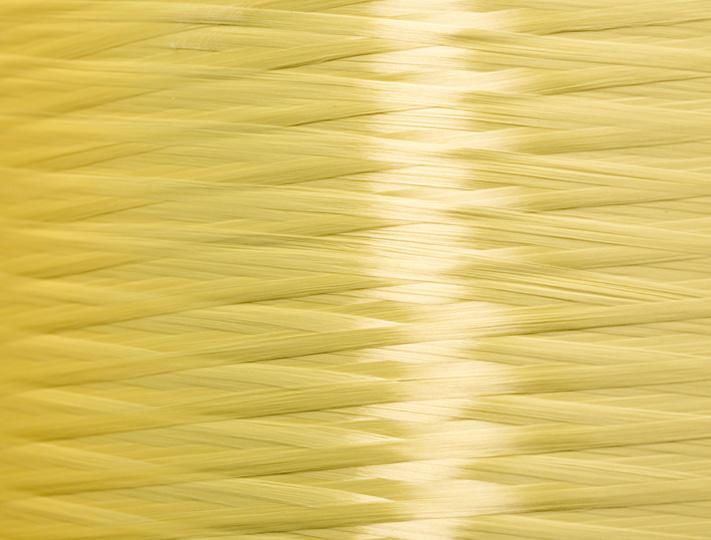

Our aramids

Our products

We produce two types of para-aramids and one meta-aramid fiber. If you would like to know more about aramids, you can find out here.

“The synergy between FibreMax and Teijin Aramid is strong. By producing our cables with Twaron®, we can develop cables with the exact length, strength, and stiffness to keep floating offshore wind turbines in place. Together with Teijin Aramid, we are building a greener future.”

Duco Handgraaf, Managing Director, FibreMax BV

R&D expert

Partnerships

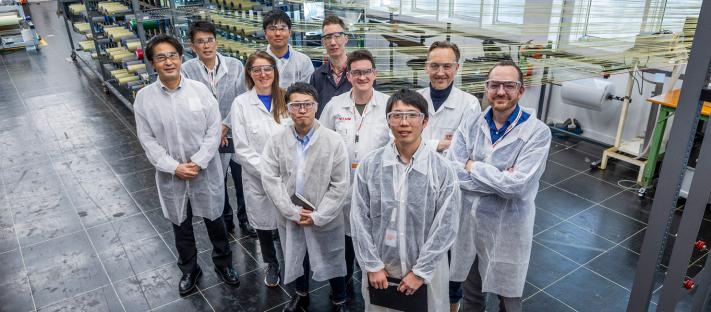

Nurturing tomorrow's innovators

Our hands-on internships and graduate projects are immersive experiences, guided by exceptional mentorship. They align academic aspirations with real-world applications, providing mutual value. Interns are an integral part of our dynamic environment, gaining insights from diverse and engaged experts.

Updates

Meet our experts

Our skilled professionals are always ready to share their expertise and insights. Learn more about our experts, stay updated with our presence at various industry events, and delve into our latest stories here.

Contact

Reach out to us

Looking to harness the power of our expertise for your project? Reach out to us for insights, collaboration opportunities or information. Our experts are ready to engage and drive your ideas.