Proven strength for demanding conditions

Technora® delivers consistent performance under pressure. With high tensile strength, fatigue resistance, and stability at elevated temperatures, it supports long-term reliability across a wide range of industries. From mechanical stress to chemical exposure, Technora® is built to perform in environments where material failure is not an option.

*vs. 0.3 years for standard para-aramids

What is Technora®?

Premium para-aramid for long-term performance

Technora® is a high-performance para-aramid developed and produced by Teijin Aramid in Japan. Its unique copolymer structure provides long-term strength, thermal stability, and resistance to fatigue and chemicals. Trusted in offshore mooring and industrial belts and hoses, Technora® supports reliable operation in industries where materials are pushed to their limits.

How does Technora® perform?

Engineered to perform in the toughest environments

Technora® combines high tensile strength with resistance to heat, fatigue, and chemicals, making it a trusted choice for components that operate under constant and dynamic load and environmental stress. The sections below detail how Technora® performs across key properties to support reliable performance over time.

High strength with stable performance under load

Technora® delivers a tensile strength of 3.1 to 3.6 GPa, offering high load-bearing capacity at low weight. With a modulus between 66 and 84 GPa, it provides the stiffness needed to limit elongation under stress. This balance of strength and dimensional stability supports reliable performance in applications where mechanical loads are constant or variable over time.

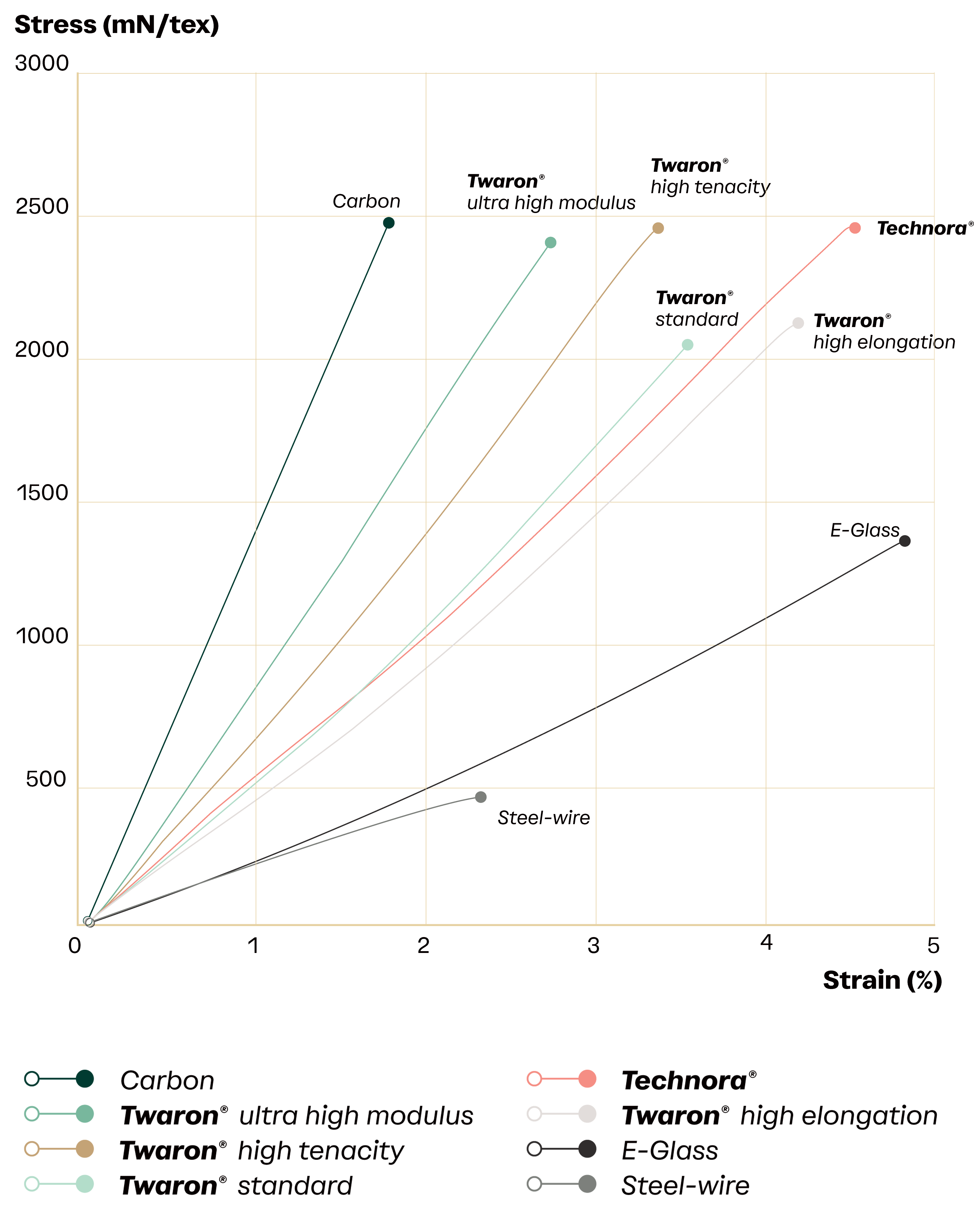

Stress-strain behavior

The stress-strain curve for Technora® shows a combination of high tensile strength and limited elongation. Compared to other high-performance fibers, Technora® maintains flexibility without compromising structural integrity. This makes it well suited for reinforcements that must absorb tension without failing, such as belts, cables, and composite structures.

Resistance to deformation

Technora® is engineered to maintain its shape under sustained load. It resists creep, shows no shrinkage in hot air, and maintains structural consistency across a wide temperature range. These properties contribute to long-term dimensional stability in components exposed to tension, pressure, or elevated heat.

Resistance to cyclic loading

Technora® maintains structural performance under repeated flexing, bending, or vibration. Its unique copolymer structure provides excellent fatigue resistance, supporting durability in applications where materials are subjected to dynamic stress over long operating cycles.

Thermal aging and creep performance

Technora® retains its strength over long periods at elevated temperatures. At 90°C, it maintains performance for over 10 years, compared to just 0.3 years for standard para-aramids. At 60°C, its projected lifespan exceeds 400 years. This resistance to thermal degradation reduces loss of mechanical properties and supports long-term performance in heat-exposed systems.

| Temperature | Standard para-aramids | Technora® | |

|---|---|---|---|

| 40 °C | 104 °F | 20 y | |

| 60 °C | 140 °F | 3 y | 400 y |

| 90 °C | 194 °F | 0.3 y | 10 y |

| 100 °C | 212 °F | 3.6 y | |

| 140 °C | 284 °F | 40 d | |

Thermal resistance in extreme environments

Technora® performs reliably across a wide temperature range. It has no melting point and decomposes only at 500°C (932°F). In continuous use, it maintains strength up to 200°C (392°F) and can tolerate short-term peaks of 400°C (752°F). Long-term exposure tests show that Technora® retains approximately 50% of its original strength after 54 days at 250°C (482°F), supporting durability in systems exposed to sustained heat.

Low-temperature stability

Technora® remains structurally stable at temperatures as low as –200°C (–328°F). It does not become brittle in subzero conditions, making it suitable for applications that operate in cold climates or experience rapid thermal cycling.

Flame resistance and fire behavior

Technora® is inherently flame resistant. It does not melt or drip when exposed to fire and is self-extinguishing. A high limiting oxygen index (LOI) further supports safe performance in high-temperature or flame-prone environments. Its low thermal conductivity also helps reduce heat transfer within layered systems.

Resistance to chemicals and solvents

Technora® offers strong resistance to a wide range of industrial chemicals, including hydrocarbons, organic solvents, acids, and alkalis. Its copolymer structure and closed filament morphology limit chemical penetration, helping the fiber maintain integrity in corrosive environments.

Stable across harsh conditions

Technora® is stable across a wide pH range, though exposure time and chemical concentration can influence resistance. These properties make it a reliable choice for reinforcement in oil and gas systems, chemical processing lines, and marine applications where material degradation poses a risk to long-term performance.

Environmental durability

With low moisture uptake and high dimensional stability, Technora® retains its properties under fluctuating humidity and exposure to environmental stress. It supports consistent performance in applications where materials must resist both mechanical load and chemical exposure over time.

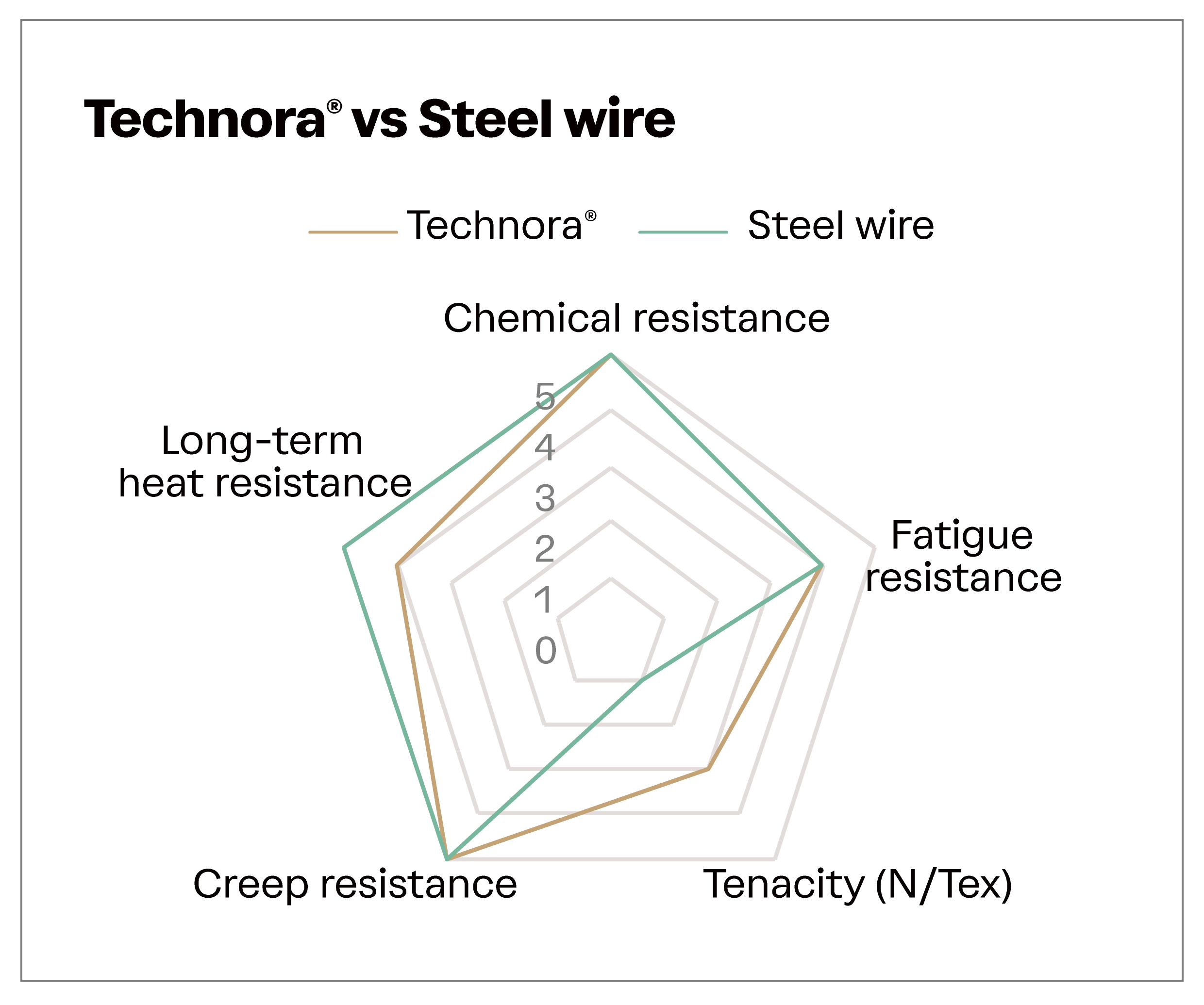

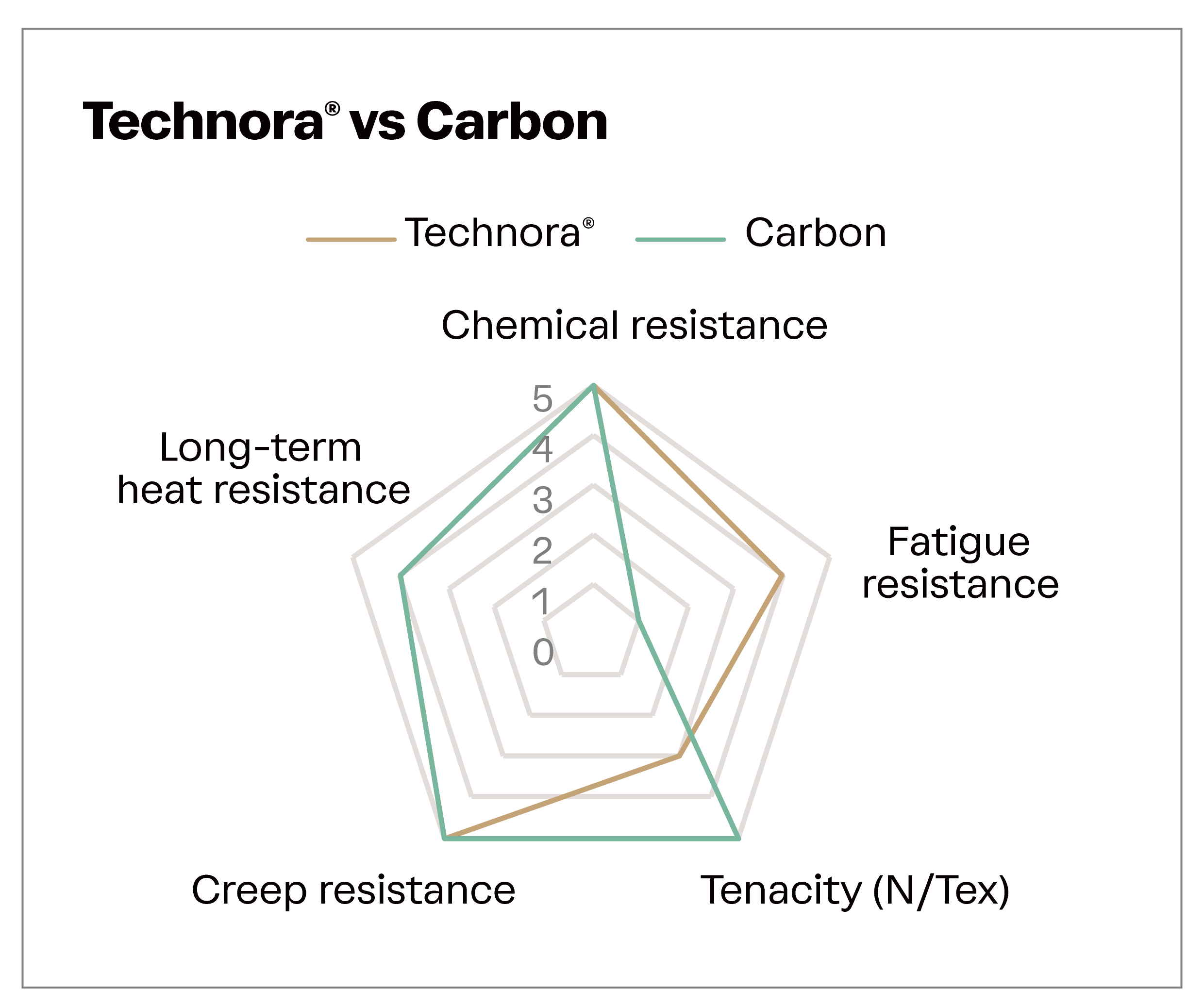

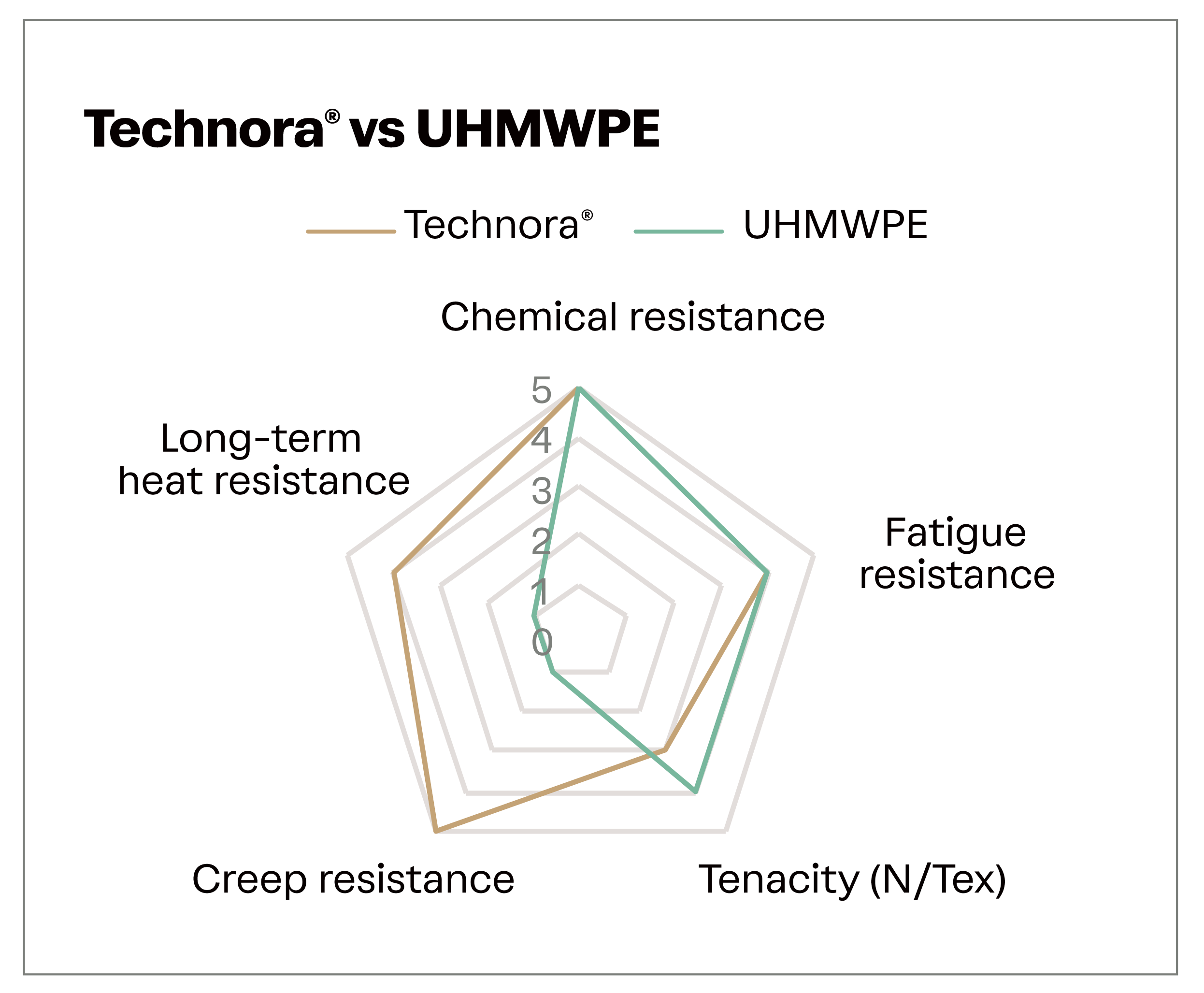

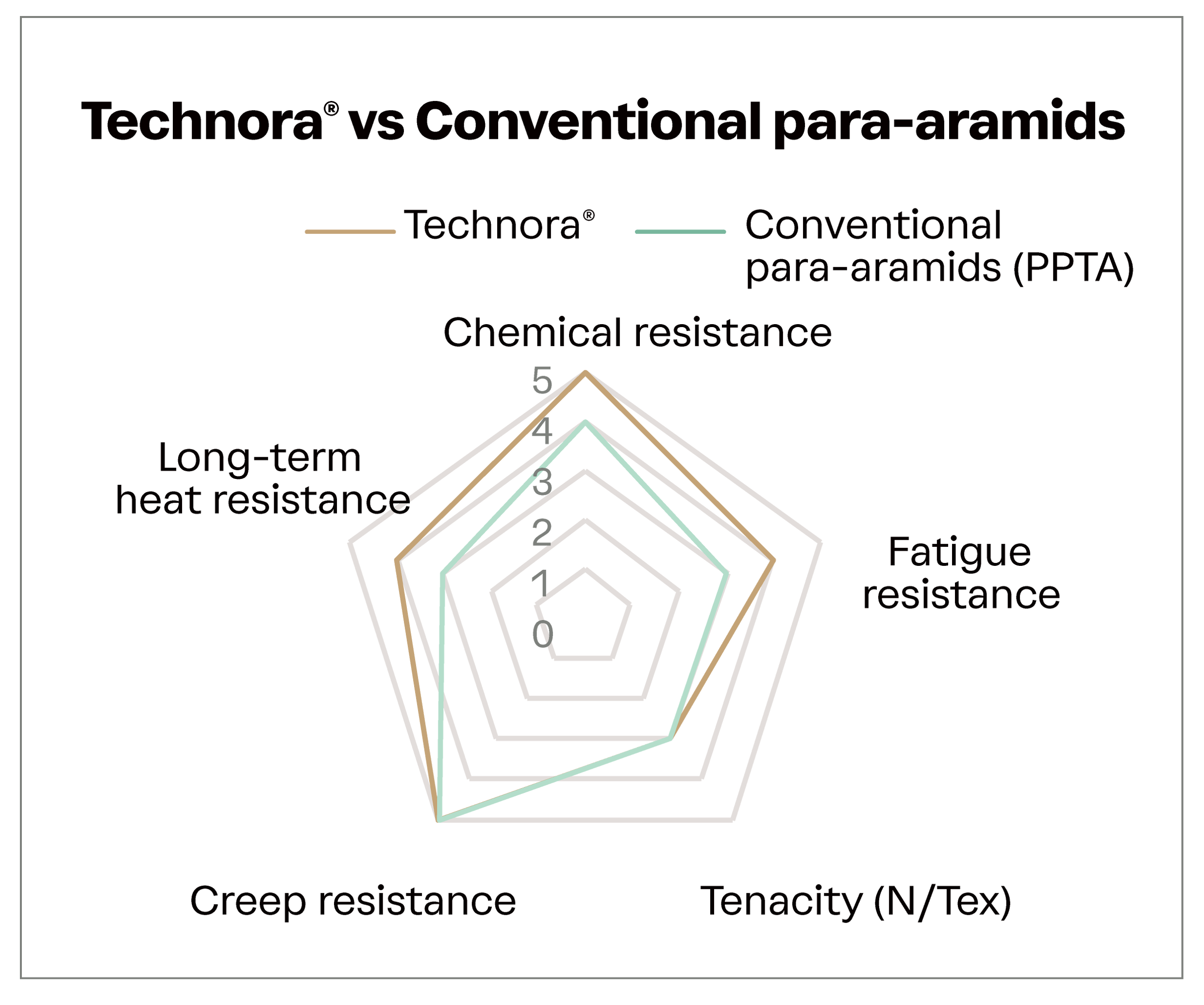

Consistent performance across critical properties

Technora® combines the core advantages of high-performance para-aramids with enhanced resistance to fatigue, heat, and chemicals. Its copolymer structure supports long-term durability in environments where materials are exposed to mechanical load, thermal cycling, and chemical stress.

Benchmarking against commonly used materials

Internal testing shows that Technora® offers a well-balanced profile across key performance metrics. Compared to materials such as steel wire, carbon fiber, UHMWPE, and conventional para-aramids, it delivers strength, dimensional stability, and fatigue resistance while maintaining thermal and chemical integrity over time.

Supporting reliable material selection

This combination of properties makes Technora® a dependable choice for reinforcement in high-performance applications. It supports consistent performance over time and helps reduce material degradation in systems exposed to dynamic, thermal, or chemical challenges.

What types of Technora® are manufactured?

Tailored for long-term performance

Technora® is produced in multiple formats to support specific processing and application needs. Each type offers a distinct balance of strength, flexibility, and durability.

Technora® filament yarn

Technora® filament yarn delivers high strength and dimensional stability for demanding applications. Available in natural gold or dope-dyed black/dark grey, with linear densities from 60 dtex, it offers high tenacity, minimal creep, and thermal resistance up to 200°C (392°F) continuous. Suitable for use in marine ropes, hoses, technical fabrics, and protective clothing.

Technora® stretch-broken yarn

Technora® stretch-broken yarn combines strength with flexibility. Its fluff-like structure increases surface area, improving rubber adhesion and fatigue resistance. With intermediate tenacity and enhanced bonding performance, it is ideal for turbocharger hoses, timing belts, and high-durability rubber reinforcements.

Technora® staple fiber

Technora® staple fiber provides excellent heat and abrasion resistance with structural flexibility. With a degradation threshold above 500°C (932°F) and optimized fiber length (51 mm, 1.7 dtex), it performs reliably in harsh environments. Applications include firefighting clothing, industrial workwear, and racing suits.

Technora® short-cut fiber

Technora® short-cut fibers are designed for precision reinforcement in high-performance composites. Available in lengths from 1 to 30 mm, they offer high strength, chemical resistance, and thermal stability above 200°C (392°F). Used in resins, cement, and rubber compounds requiring uniform dispersion.

What makes Technora® different?

Frequently asked questions

Find quick answers to common questions about our Technora® aramid products. If you need more help, our team of experts is here for you.

Where is Technora® produced?

Technora® is developed and manufactured in Matsuyama, Japan. Since its commercial launch in 1986, it has been used in critical applications across the automotive, oil and gas, marine, and industrial sectors.

How is Technora® different from other para-aramids?

Technora® has a unique copolymer structure that provides improved resistance to fatigue, abrasion, and heat compared to conventional para-aramids. This enables reliable long-term performance under dynamic load, elevated temperatures, and chemically aggressive environments.

What makes Technora® suitable for harsh environments?

Technora® remains stable across a wide operating range, from –200°C (–328°F) to 200°C (392°F), and withstands acids, alkalis, hydrocarbons, and solvents. This makes it highly reliable for applications exposed to both thermal and chemical stress.

How does Technora® support long-term value?

By resisting thermal aging and chemical degradation, Technora® extends component service life. At 90°C (194°F) it maintains strength for more than 10 years, reducing replacement cycles and improving system reliability.

Get in touch with our aramid experts

Do you have technical questions about our aramid solutions, specifications, or applications? Fill out the contact form to speak directly with our material experts. We’re ready to provide detailed insights and discuss how our solutions can meet your specific needs.