There’s no manual for building a car like Nuna 13

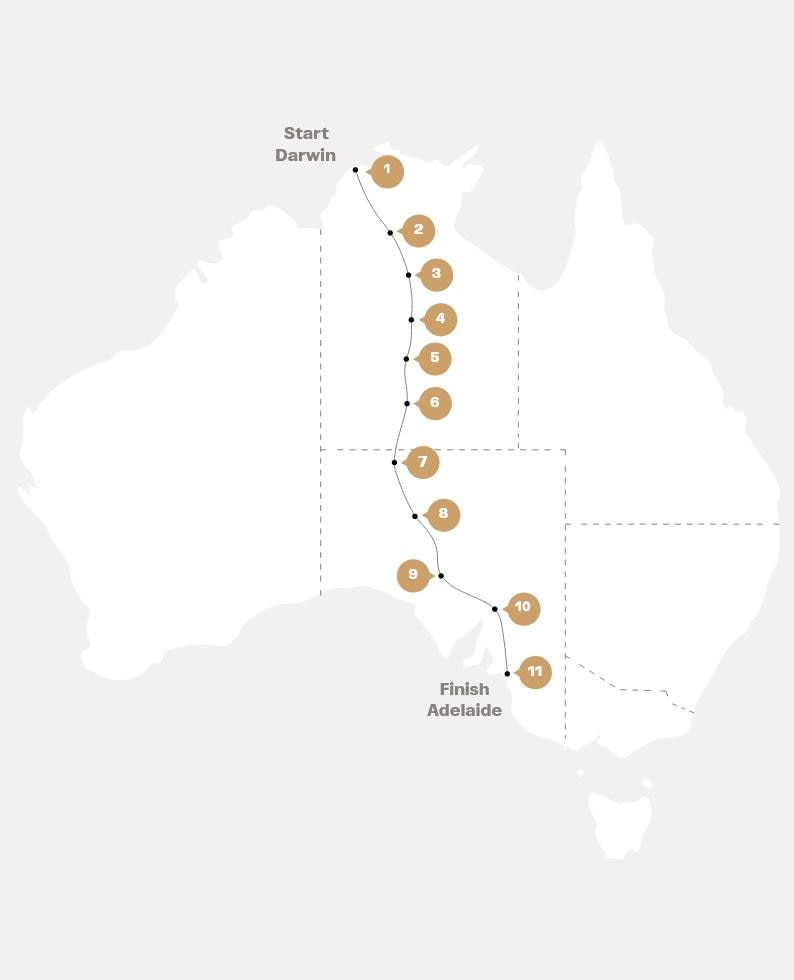

What does it take to build a solar car that can handle the Australian Outback? For the Brunel Solar Team, it meant questioning whether every part of Nuna 13 could handle the pressure of a 3,000 km journey across Australia.

So they engineered it with intent, supported by partners and materials that helped the design hold up under real-world conditions. And the result shows what innovation depends on.

Trailer

From concept to finish line

The Brunel Solar Team had one chance to get it right. Nuna 13 is the outcome.

Series

Inside the journey

Follow the Brunel Solar Team through the moments that defined Nuna 13 and see how advanced materials and team collaboration came together. Watch the latest episode

Follow the stories shaping performance

Sign up for update, stories and insights from across our projects.

Team

The students behind the car

Nuna 13 was built by a team of 18 students from TU Delft, each taking a year off their studies to push solar performance further. Their backgrounds range from aerospace engineering to applied physics. We spoke with four of them about the challenges and decisions behind the project.

Students from our story

Aramid connection

Nuna 13 and Twaron Next®

Bridgestone solar car tires with its ENLITEN™ technology on Nuna 13 include a belt layer reinforced with Twaron Next®. This new para-aramid combines high strength and stiffness with low weight to help keep the tire stable at speed and under load. Its circular content supports a more responsible approach to reinforcement by connecting material performance with environmental goals.

Stories

Stories from the road and beyond

Go inside the builds, materials, and thinking that make performance possible. New stories and updates will be added as the journey continues.

Media kit

Download the media kit

Access press releases, approved visuals, technical information, and details on the team that built Nuna 13. This kit includes images and story points to support accurate coverage.

FAQ

Dive deeper

About the Car

1. What is the solar car made of?

The car is made from prepreg carbon fiber, cured in an autoclave to maximize strength and minimize weight. In addition, it is equipped with Bridgestone solar car tires with its ENLITEN™ technology, which are reinforced with Twaron Next®. Every component is custom-designed to remove unnecessary material and support efficiency over long distances.

2. How fast can the car go, and what is its range?

The car can reach speeds of up to 130 km/h under race conditions. It carries a 3 kWh battery, which is significantly smaller than a typical EV battery. Despite this, it can travel up to 300 kilometers on battery power alone, thanks to its lightweight design and high energy efficiency

3. How much does the solar car weigh?

The car weighs approximately 160 kilograms. The weight was measured during internal testing ahead of the official race inspection.

4. How is the car powered, and how many solar cells does it use?

The car is powered by high-efficiency silicon solar cells, covering the maximum allowed surface area of 6 square meters. Energy from the cells charges a compact battery and drives a custom in-wheel motor designed for minimal energy loss.

5. How did the engineers reduce drag and improve aerodynamics?

The team used a shape-solving algorithm to generate thousands of possible car shapes, which were refined through computational fluid dynamics (CFD) simulations. The final design was validated in a full-scale wind tunnel test. The resulting drag is comparable to that of a passenger car’s side mirror.

6. What are the biggest technical challenges when building a solar car?

Designing a car that is both lightweight and durable is a core challenge. It must perform reliably under real-world conditions, including extreme temperatures, crosswinds, cattle grids, and road debris, all while conserving as much energy as possible.

7. Where is Twaron® used in the car and why?

Twaron Next® is used by Bridgestone to reinforce the solar car tires chosen by the team, which equip its ENLITEN™ technology, and has contributed to enhancing the tire’s performance and environmental profile. In addition, Twaron® was used as a fire-resistant shield in the cockpit to enhance driver safety and protect critical components.

8. How do materials like Twaron® contribute to strength and weight reduction?

Twaron® has a high strength-to-weight ratio, excellent thermal resistance, and durability under repeated stress. In tire reinforcement, these properties help create a stronger belt without adding unnecessary weight, contributing to improved handling and overall performance.

9. What’s different about the 2025 car compared to previous designs?

The 2025 car marks a decisive step forward from previous designs. A 6 m² solar panel, 1.5 times larger than those used in the past decade, captures more energy, while the 3kWh battery is only one-third the size of earlier versions. These changes shift the balance between storage and generation. The car also features an asymmetric catamaran body for aerodynamic efficiency and crosswind stability, a custom ironless in-wheel motor with up to 98 percent efficiency, and a lightweight battery pack built with Amprius high-energy-density cells using advanced silicon anode technology. The result is a system optimized for efficiency and weight savings.

10. What happens if something breaks during the race? Do you carry spare parts?

The support team carries essential spare parts, including tires, suspension components, and electronics. Roadside repairs are often needed under time pressure and harsh conditions, so the car is designed with modular components for quick replacement.

About the Brunel Solar Team

11. Who are the students behind the Brunel Solar Team?

The team consists of full-time students from Delft University of Technology who dedicate a full year to the project. Their disciplines include engineering, industrial design, computer science, communications, and business.

12. How many times has the team competed in the World Solar Challenge?

The Brunel Solar Team has competed in every edition of the Bridgestone World Solar Challenge since 2001. The 2025 race marks the team’s 12th participation. Each year, a new group of students takes over development, refining the car’s design to meet current race conditions and regulations.

13. How many times has the team won or placed on the podium?

With seven victories, the Brunel Solar Team is the most successful participant in the history of the Bridgestone World Solar Challenge. The next closest competitor has only two wins, and it would take more than a decade to close the gap.

14. How long does it take to build a solar car from start to finish?

From concept to race-ready vehicle, the process takes about 12 months. For the 2025 car, the team spent six months on design, four months on building, and two months on testing.

15. What fields of study do the team members come from?

Students come from a variety of academic backgrounds, including mechanical engineering, aerospace, electrical engineering, applied physics, computer science, and industrial design.

16. How do students balance engineering work with their studies?

Team members take a break from their formal studies to focus exclusively on the project. This full-time commitment allows them to operate like a startup, managing every technical and operational aspect of the car.

17. What does a typical day look like during the race?

The team starts before sunrise to prepare for charging. Driving begins at 8:00 a.m. and continues until 5:00 p.m., with real-time monitoring of performance and weather. Evenings are used for repairs, strategy updates, and data analysis.

18. How do you test the car before race day?

Testing includes component-level validation, dynamic road trials, full-day endurance runs, and simulations of race conditions. The 2025 car, Nuna 13, was also tested in a full-scale wind tunnel.

19. What lessons do students take from the project into their future careers?

The experience builds hands-on engineering skills, systems thinking, project management, and leadership. Many alumni follow careers in clean energy, mobility, aerospace, and advanced technology.

About Teijin Aramid and Twaron®

20. What is Twaron®?

Twaron® is a high-performance aramid fiber developed by Teijin Aramid. The material helps maintain tire shape and reduce energy loss during driving. Bridgestone uses Twaron Next®, an advanced version of the fiber, in tires for the 2025 Bridgestone World Solar Challenge.

21. What are the advantages of Twaron® compared to carbon fiber or steel?

Twaron® is five times lighter than steel and more flexible than carbon fiber. It resists fatigue, maintains its strength when exposed to heat, and does not corrode. These characteristics make it ideal for applications where weight and durability are both critical.

22. How does Teijin Aramid support solar teams like Brunel?

We supply Twaron Next® to Bridgestone, which manufactures the tires fitted to the Brunel Solar Team’s vehicle.

23. What makes Twaron Next® a more sustainable aramid?

Twaron Next® is produced using a more environmentally responsible process that includes circular content, bio-based solvents, and lower-emission manufacturing. It delivers the same strength and performance as standard Twaron®, but with a reduced carbon footprint. These innovations support more sustainable material choices in engineering applications.

24. What other industries use Twaron®, and what for?

Twaron® is used in tire reinforcement, ballistic protection, deep-sea mooring lines, fiber optic cables, and automotive components such as hoses and belts. It is chosen for its durability, thermal resistance, and high strength-to-weight ratio.

About Bridgestone and the Tires

25. How do Bridgestone and Teijin Aramid work together on tires?

Bridgestone integrates Twaron Next® into the belt layer of solar car tires using its ENLITEN™ technology. Twaron Next® has contributed to enhancing the tire’s performance and environmental profile. We provide the fiber; Bridgestone designs and manufactures the tires. Development of the aramid fiber is done as a collaboration within the project parameters.