Industry value

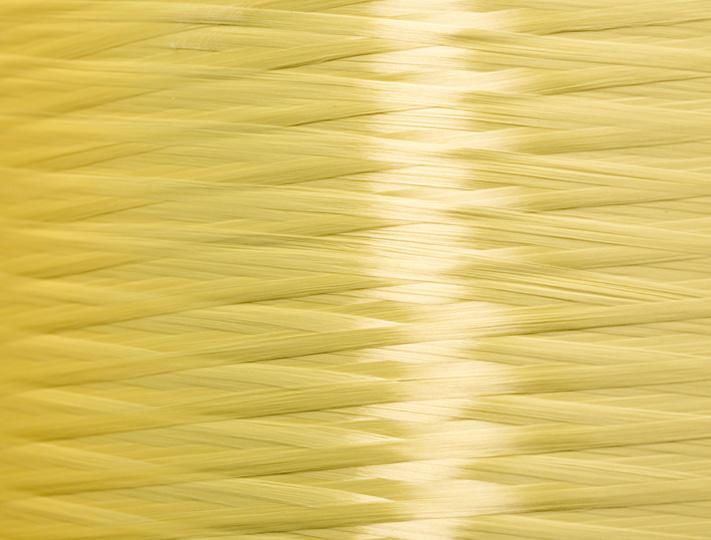

Redefining safety through aramid innovation

Teijin Aramid has provided para- and meta-aramid materials for protective wear for over 50 years. Our mission is twofold: enhance the performance of safety gear and reduce its environmental impact. Through continuous innovation, we address industry challenges, focusing on both product efficiency and sustainability.

Solutions

Protecting those who need it most

We actively partner with you to deliver the best solution – no matter your industry. From industrial workers and police to emergency responders and beyond, our priority is flame resistance and durability that doesn’t compromise on protection.

Industrial workwear

Industrial workwear made with Twaron® protect against heat, cuts, and mechanical hazards. Teijinconex® and Teijinconex® neo protect against heat, flames, and electric arc. In addition to providing protection, workwear made with our aramids is more durable and offers a longer lifespan than traditional flame-resistant workwear.

Racing suits

Racing suits made with our aramid fibers help drivers stay focused—thanks to certified, breathable protection that reduces weight, enhances comfort, and minimizes heat stress.

"The integration of Teijin Aramid's fibers has transformed our product line. Our customers now benefit from gear that offers superior protection while being lightweight and comfortable."

Michael Batson, Director of Innovation, True North.

Our aramids

Sustainability

Leading in sustainable PPE

Protecting life goes beyond just personal protective equipment. Our ambition is to protect those in danger while also protecting our environment from PPE waste going to landfills.

Teijin Aramid works closely with our partners to create a circular value chain. Our actions include:

Take-back | Recycling | Life-cycle assessment |

|---|---|---|

| We collaborate to reclaim end-of-life garments and partner with organizations that recycle aramid fibers. | We work with partners to optimize recycling technologies, reduce energy and aim for carbon neutrality through the reuse of aramids. | We evaluate financial and environmental impacts from production to end-of-life, offering insights for sustainable, cost-effective operations. |

Protective wear expert

Updates

New and upcoming

We are present at many of the major trade shows and seminars on PPE globally. Check our planned events, or read one of the stories on our work in the life protection industry.

Get in touch

Let’s share ideas and expertise

Interested in exploring protective solutions with us? Contact us if you have ideas and projects to share, or need further information. We’ll have the right expert get in touch.