Enhancing performance and longevity

Twaron® boosts durability, stability and efficiency in the most demanding applications. With high resistance to heat, fatigue, and creep, Twaron® strengthens products and extends service life across industries – from automotive to renewable energy.

*On a weight for weight basis

What is Twaron®?

Advanced para-aramid for extreme applications

Twaron® is a high-performance synthetic polymer fiber, classified as a para-aramid, manufactured by Teijin Aramid in the Netherlands. Engineered for extreme mechanical loads, it offers high tensile strength, resistance to heat and chemicals, and minimal creep under sustained stress. With 50 years of expertise in aramid development, we work closely with industry partners to customize Twaron® for demanding applications, from ballistic protection to high-performance composites.

How does Twaron® perform under stress?

Precision-engineered for critical applications

Twaron® delivers data-backed durability that engineers can rely on for structural reinforcements, wear resistance, and high-temperature performance. Below is a breakdown of key performance attributes to help you identify the most effective solution for your application.

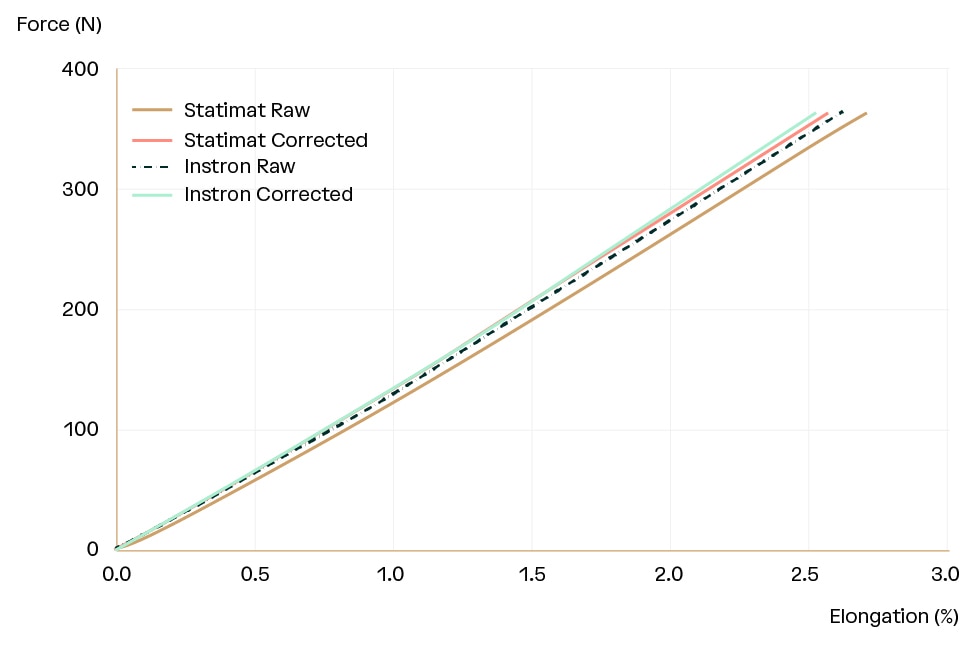

The modulus and elongation of Twaron® are critical to its performance in engineering applications that demand reliability and precision. Our approach includes corrections for tensile tester influences, using ASTM D7269 standards to ensure that every measurement accurately reflects our aramid’s capabilities under stress.

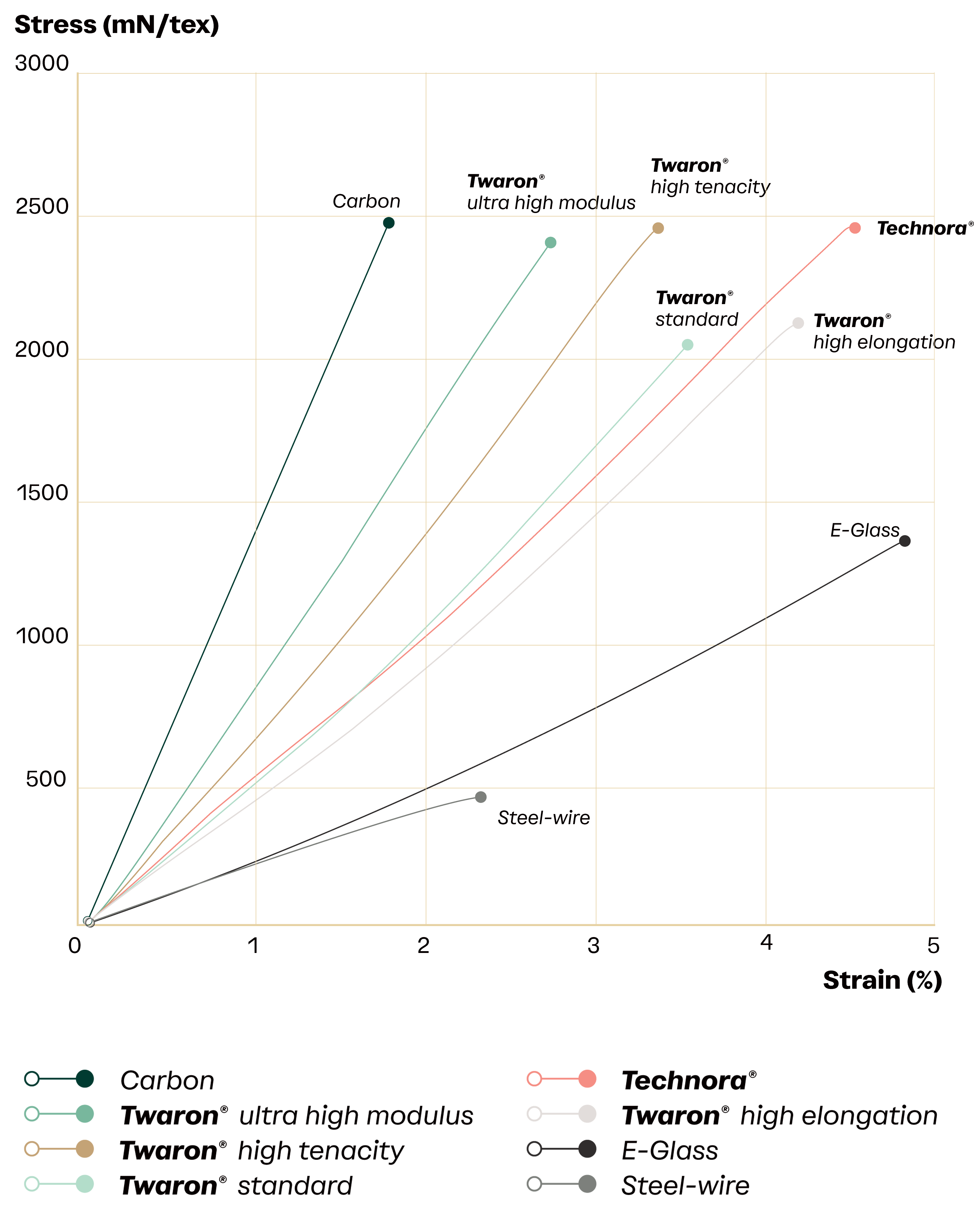

Modulus

With a modulus between 60 and 145 GPa, the high stiffness of Twaron® minimizes deformation under significant tensile forces, making it invaluable for demanding applications like automotive reinforcements and submarine power cables. These applications require materials that can retain structural integrity even under extreme loads, ensuring safety and performance consistency. The high modulus of Twaron® is particularly effective in settings with both static and dynamic stress assuring dimensional stability and enabling it to maintain strict tolerances that support optimal functionality over prolonged operational periods, even in harsh or variable conditions.

Figure 1: Stress/strain curve of various materials

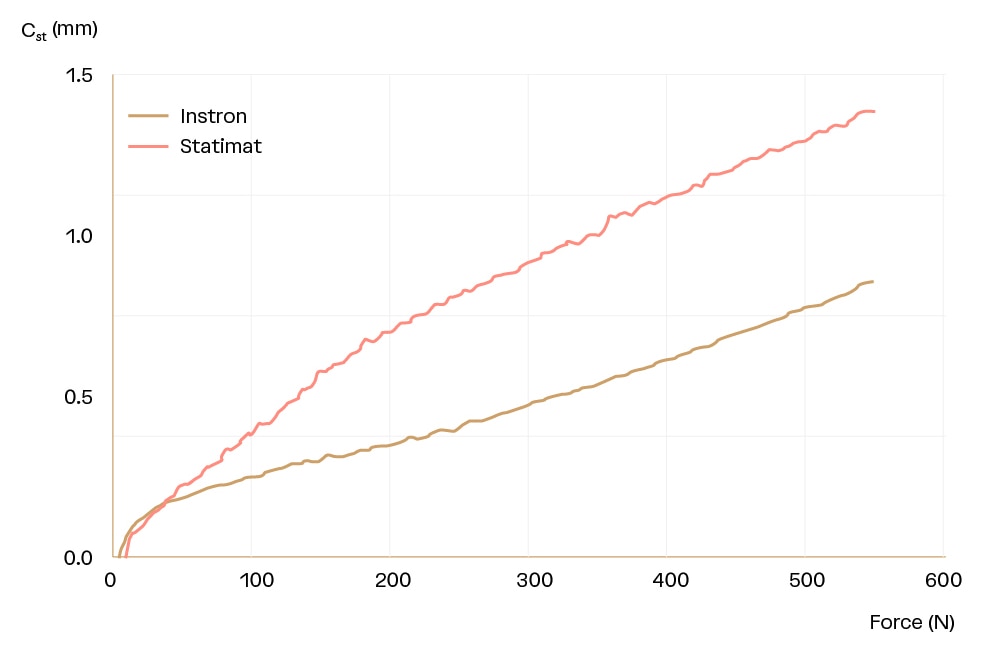

Data correction in Twaron® performance metrics

To ensure that performance metrics reflect real-world conditions, rigorous correction processes account for the influences of testing equipment, even beyond what is described in ASTM D7269. A tensile tester is not infinitely rigid; both the frame and load cell deform under applied force, introducing variability into stiffness measurements. These variations arise from differences in tensile tester designs, load cell mechanics, and gripping systems. Factors such as clamp type, bollard shape, surface finish, and the interaction between the bollard and yarn surface all influence the test.

The deformation of the tensile tester and variations in gripping can also vary throughout the test, influencing the accuracy of the results. By implementing optimized testing methodologies, these effects can be quantified and corrected, enabling the generation of measurement curves that more accurately represent the material’s true performance. Below, typical corrected curves are shown for reference.

Figure 2: Raw and corrected force-elongation curves for twisted Twaron® 1610 dtex yarn

Figure 3: Tester contribution Cst for the Instron and Statimat tensile testers for twisted Twaron® 3220 dtex yarn

* The values presented on this page offer a general overview of Twaron® properties across product lines and are approximated for simplicity. Given the unique demands of each application, these figures may not fully capture the specific characteristics required for your needs. For precise, application-specific data and detailed insights, please contact our team.

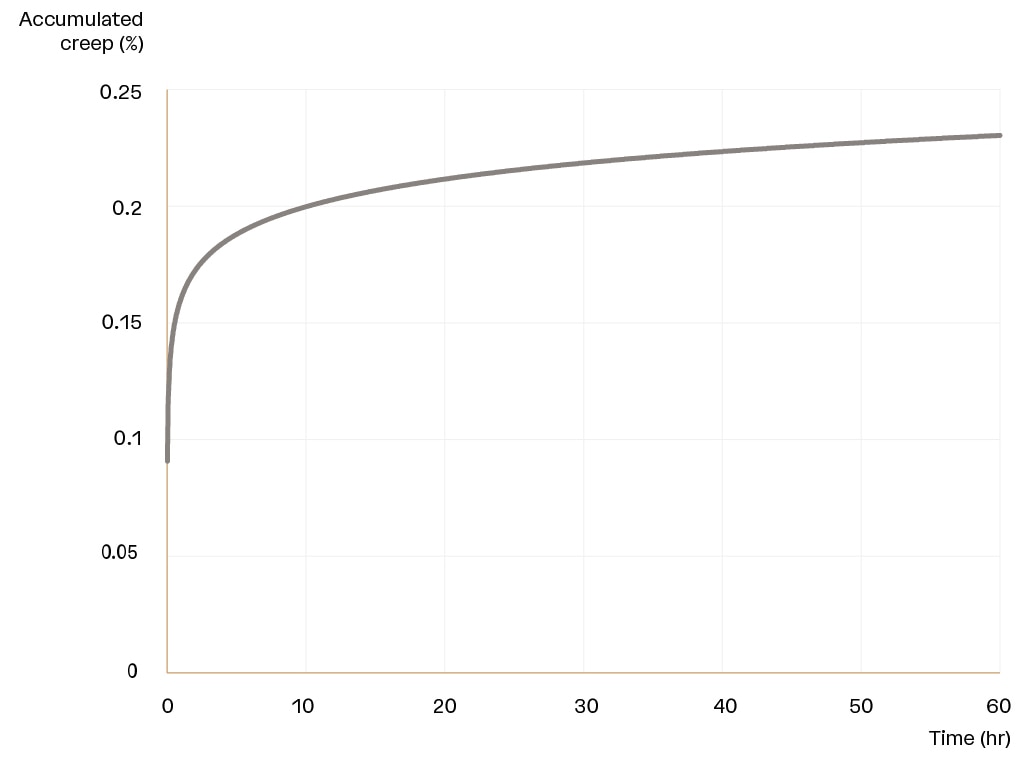

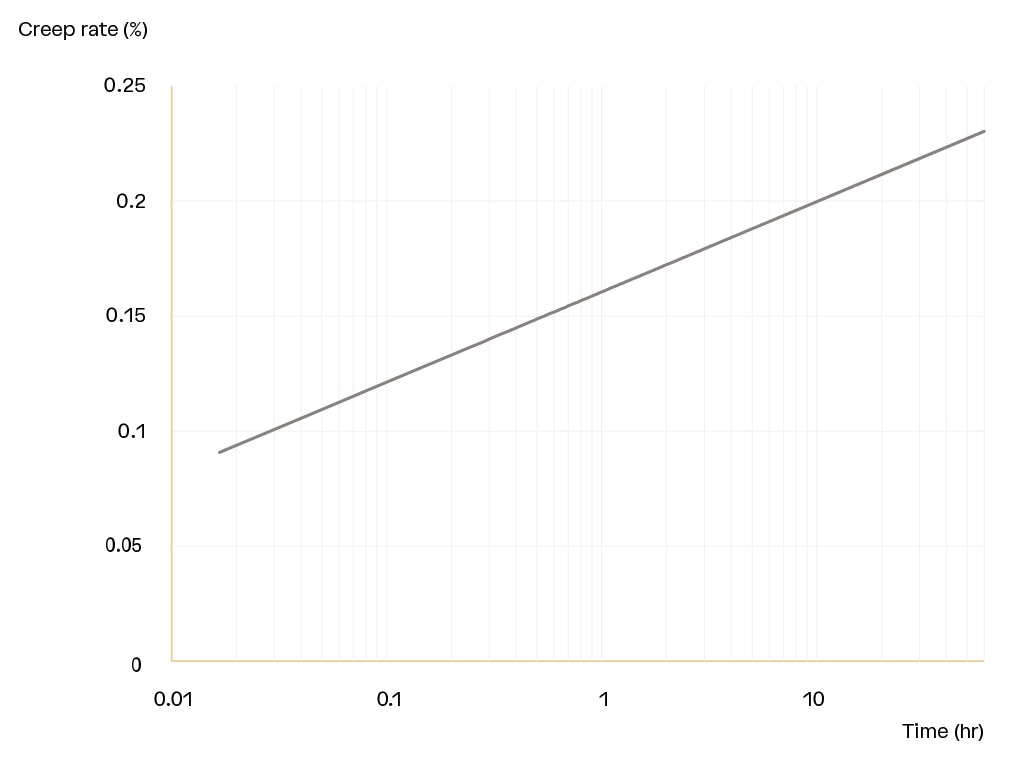

Creep resistance is a defining feature of Twaron® in high-load applications where long-term dimensional stability is crucial. Engineered for environments that demand minimal elongation over time, Twaron® performs reliably under sustained stress, maintaining its structural integrity even in prolonged, high-stress conditions. This controlled creep behavior makes it ideal for demanding applications such as tension-leg platforms, industrial ropes, and optical fiber cables, where even small changes in length could compromise functionality.

Twaron® follows a well-defined primary creep phase, during which most elongation occurs within the first hours or days of loading, followed by a long-term, minimal creep rate that stabilizes. The constant logarithmic creep rate of Twaron® means that the creep that is accumulated in the first 6 weeks will only be doubled after 114 years.

Figure 4: Creep accumulation of Twaron 2300 1680 dtex at 100 N for 60 h.

This behavior is due to the fiber's viscoelastic properties, where initial stress induces a rapid, diminishing rate of elongation that eventually reaches a steady state. The steady-state or secondary creep rate remains so low that, beyond the primary phase, further elongation is often negligible within the fiber’s economic lifespan. This stability is particularly valuable in high-load applications, as the fiber retains structural integrity over decades of use.

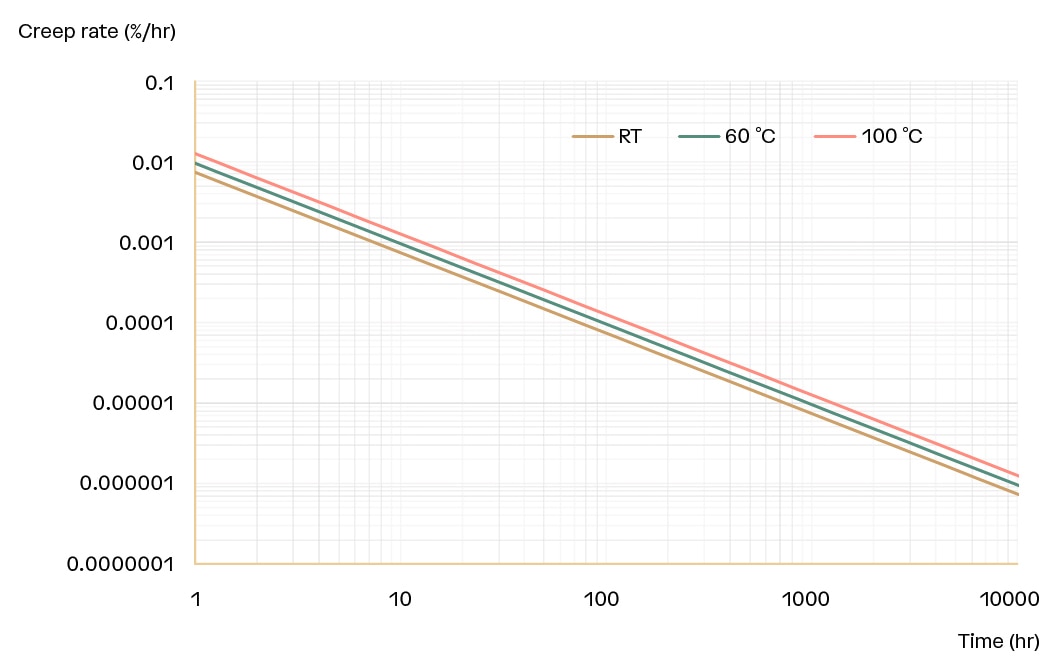

Compared to other materials, such as ultra-high molecular weight polyethylene (UHMWPE), Twaron® demonstrates superior performance by resisting the marked upswing in creep rate often seen at elevated temperatures.

Figure 4: Fitted constant logarithmic creep rate of Twaron 2300 1680f1000 at 600 mN/tex at various temperatures as function of logarithmic time.

This resistance to temperature-induced creep changes makes Twaron® ideally suited for applications requiring endurance across diverse environmental conditions without compromising load-bearing capability. With reliable performance under continuous stress, Twaron® enhances the operational security and longevity of critical infrastructure.

Twaron® combines high electrical resistivity with stable dielectric performance over a wide range of frequencies, making it an effective material for applications requiring electromagnetic transparency and insulation. Its low dielectric constant, minimal energy dissipation, and resistance to charge accumulation support reliable performance in optical fiber cables (OFCs), antenna reinforcement, and high-frequency communication systems.

Electrical insulation and resistivity

Twaron® serves as an effective electrical insulator, with resistivity values ranging from 3.1×10³ Ω·m to 7.5×10⁵ Ω·m, depending on the fiber type and surface finish. Positioned at the lower end for insulating materials, this resistivity helps prevent unintended current leakage, making Twaron® suitable for high-voltage applications, battery boxes, and other areas where electrical shorts could pose a safety risk. When used in armored AC power cables, Twaron® eliminates losses from Eddy currents that are typically associated with steel. Additionally, the resistivity of Twaron® can be tailored by adjusting or removing the surface finish.

Yarn type | Linear | Filament | Type of | Amount of | Electrical | Electrical | |

|---|---|---|---|---|---|---|---|

| Twaron® | |||||||

| 1 | Twaron® 1000 | 1680 | 1000 | Spin finish | 0.8 | 1.2x1011 | 1.4x104 |

| 2 | Twaron® 2300 | 1680 | 1000 | Spin finish | 0.6 | 1.0x1013 | 1.2 x 106 |

| 3 | Twaron® 2200 | 1610 | 1000 | Spin finish | 0.8 | 2.0x1012 | 3.0x105 |

| 4 | Twaron® 2200 | 3220 | 2000 | Spin finish | 0.8 | 6.5x1011 | 1.5x105 |

| 5 | Twaron® 3200 | 2640 | 2000 | Spin finish | 0.5 | 4.0x1010 | 7.7x103 |

| 6 | Twaron® 2255 | 1610 | 1000 | Spin finish | 0.3 | 2.8x1010 | 3.1x107 |

| 7 | Twaron® 2226 | 1610 | 1000 | Spin finish | 0.8 | 6.7x1012 | 7.5x105 |

| 8 | Twaron® 2304 | 1680 | 1000 | Overlay finish | 3.0 | 3.8x1012 | 4.4x105 |

| 9 | Twaron® 2204 | 3220 | 2000 | Overlay finish | 6.0 | 2.4x1011 | 5.4x104 |

| 10 | Twaron® 3052 | 1610 | 1000 | Overlay finish | 4.0 | 5.5x1012 | 6.1x105 |

Unlike metallic reinforcements that introduce conductivity, Twaron® remains an insulator, helping to maintain signal integrity in sensitive electromagnetic environments. Its low electrical conductivity makes it suitable for high-voltage transmission lines, aerial dielectric self-supporting (ADSS) cables, and battery boxes.

Dielectric performance across frequencies

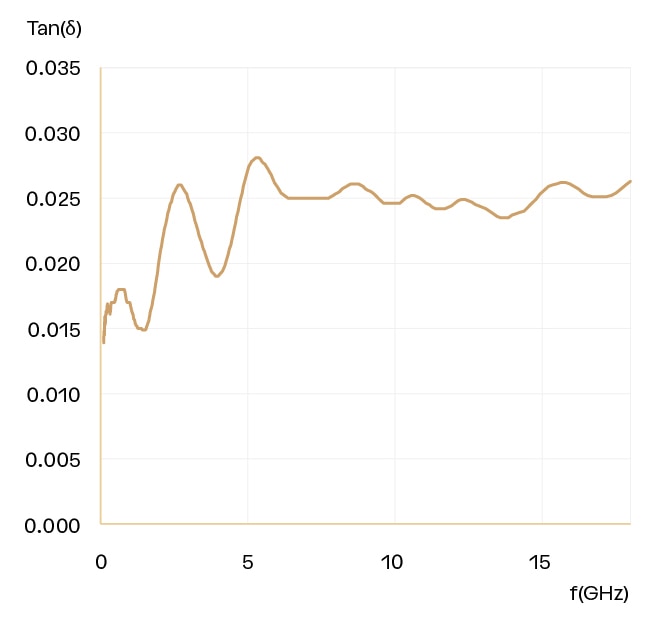

Twaron® maintains a low and stable dielectric constant across a wide frequency range, reducing electromagnetic interference (EMI). At 18 GHz, its relative permittivity (εr′) ranges from 1.97 to 2.31, depending on fiber type. This consistency helps preserve signal integrity, making Twaron® suitable for radar domes, antenna systems, and composite panels used in sensitive electronics.

Frequency | Sample 13 | sample 14 | ||||

|---|---|---|---|---|---|---|

| (GHz) | εr' | εr" | tan δ | εr' | εr" | tan δ |

| 0.1 | 2.13 | 0.033 | 0.015 | 2.15 | 0.032 | 0.015 |

| 0.2 | 2.11 | 0.037 | 0.017 | 2.13 | 0.036 | 0.017 |

| 0.5 | 2.09 | 0.036 | 0.017 | 2.11 | 0.035 | 0.017 |

| 1.0 | 2.07 | 0.036 | 0.017 | 2.09 | 0.032 | 0.015 |

| 2.0 | 2.06 | 0.041 | 0.020 | 2.09 | 0.039 | 0.019 |

| 5.0 | 2.04 | 0.049 | 0.024 | 2.06 | 0.054 | 0.026 |

| 10.0 | 2.01 | 0.049 | 0.024 | 2.03 | 0.052 | 0.026 |

| 18.0 | 1.99 | 0.052 | 0.026 | 2.01 | 0.052 | 0.026 |

| Water content (%): sample 13 3.20%, sample 14 3.17% | ||||||

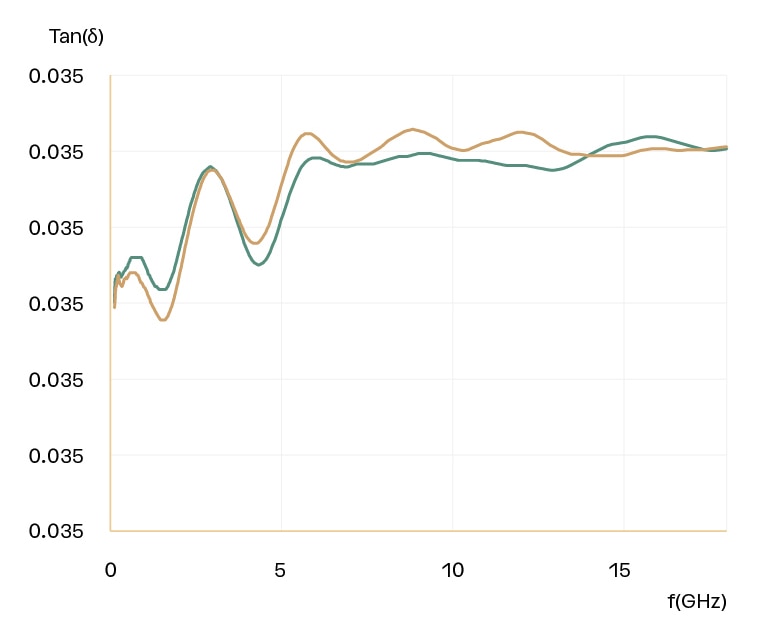

Twaron® also demonstrates low dielectric loss (εr′′) in high-frequency applications, with values between 0.052 and 0.072 at 18 GHz. Its low loss tangent (tan δ = 0.025 to 0.031) minimizes signal attenuation, ensuring clarity in wave-transmitting structures and reducing RF losses in cables.

Figure 6: Twaron® 2200 dielectris properties

Performance in high-voltage and high-frequency applications

Twaron® offers high resistivity and stable dielectric properties, providing reliable performance where low electrical losses and mechanical strength are essential. In cable applications, Twaron® delivers the required stiffness while reducing electrical losses compared to steel armor.

With consistent dielectric behavior across fiber types, Twaron® supports the design of high-strength, electromagnetic-transparent composite materials for aerospace, defense, and telecommunications applications.

Figure 7: Twaron® D3052 dielectric properties

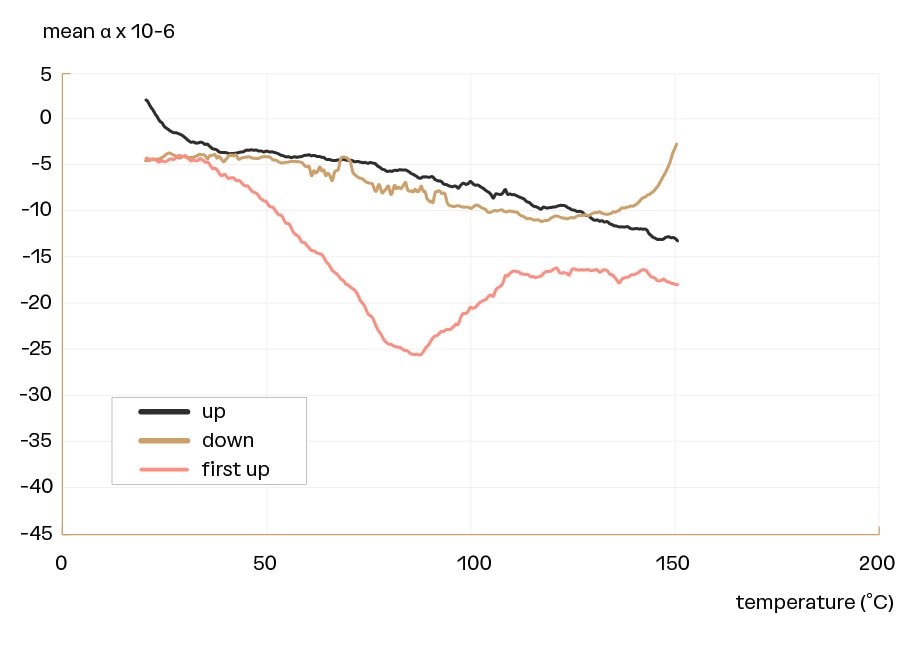

Twaron® demonstrates exceptional thermal stability, making it suitable for high-temperature applications where materials must retain dimensional and structural integrity. With a low coefficient of thermal expansion (CTE), Twaron® resists expansion or contraction across a broad temperature range, minimizing distortion in environments where even small dimensional changes can compromise functionality.

Figure 8: The actual thermal expansion coefficient of Twaron 1000 yarn as function of the temperature, for the scans up (average value of three scans), the scans down (average value of four scans) and the first scan up, respectively.

This stability is critical for applications in automotive components, industrial machinery, and protective equipment that operate under variable thermal conditions.

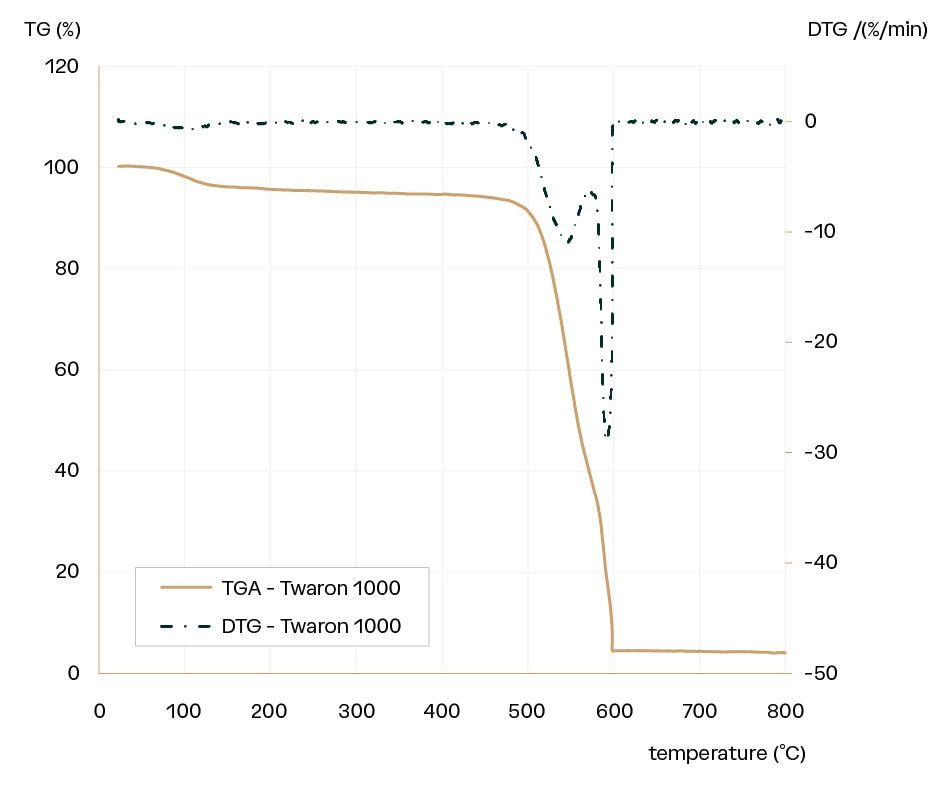

Twaron® has a decomposition temperature above 500 °C, well above the limits of materials like polyamide, HMPE, LCP and polyester, which begin to degrade and/or melt at significantly lower temperatures.

Thermal expansion coefficients | |

|---|---|

| Temperature [ °C ] | CTE [106 C-1] |

| 10 | -3.6 |

| 20 | -3.3 |

| 30 | -3.4 |

| 40 | -3.7 |

| 50 | -4.2 |

| 60 | -4.9 |

| 70 | -5.7 |

| 80 | -6.6 |

| 90 | -7.4 |

| 100 | -8.2 |

| 110 | -8.9 |

| 120 | -9.4 |

| 130 | -9.6 |

| 140 | -9.6 |

| 150 | -9.2 |

This high decomposition temperature ensures that Twaron® retains its tensile strength and structural cohesion even when exposed to prolonged heat, offering a clear advantage over other fibers in applications such as high-performance cables and heat-resistant fabrics.

Compared to materials with a higher CTE, the thermal stability of Twaron® reduces maintenance needs and enhances operational reliability by eliminating the risks associated with thermal expansion and contraction.

Burning properties for safety-critical applications

Twaron® is engineered to withstand extreme heat and maintain structural integrity in safety-critical applications, with a decomposition temperature above 500 °C. This high threshold minimizes the risk of ignition and enables Twaron® to perform effectively in environments where conventional fibers, such as polyester or polyamide, would combust or melt. Applications such as firefighting gear, electrical insulation, and aerospace components benefit from this aramid’s ability to resist ignition and sustain minimal degradation under intense heat.

The flame-resistant properties of Twaron® are further enhanced by its self-extinguishing behavior; when exposed to flame, it chars rather than melts, eliminating the risk of dripping molten material that can propagate fire. This charring characteristic helps contain fire spread, which is particularly valuable in confined spaces or crowded environments like aircraft interiors, where preventing flame spread is essential for occupant safety.

In fire scenarios, Twaron® releases lower levels of toxic gases compared to many synthetic fibers, ensuring a safer response under combustion. By emitting minimal smoke and hazardous fumes, Twaron® meets the demands of safety-critical applications. These burning properties comply with stringent safety standards, making Twaron® an optimal choice for engineers designing fire-resistant solutions in high-stakes industries.

Figure 9: TGA of Twaron® 1000 yarn measured under air

What types of Twaron® are manufactured?

Tailored for every application

Twaron® is available in different forms, each designed to meet specific performance demands. Explore the different types to find the best fit for your application.

Twaron® filament yarn

Twaron® filament yarn is available in standard modulus, high modulus, and high tenacity variants, with linear densities starting from 400 dtex. Suitable for applications like cables, tires, and ballistic protection, it is offered in natural yellow or black for tailored solutions.

Twaron® staple fiber

Twaron® staple fibers provide heat and cut resistance, ideal for gloves and protective apparel. Available in lengths from 40 to 100 mm and densities of 0.9, 1.7, and 2.5 dtex, including black options, these fibers deliver reliable performance in safety applications.

Twaron® short-cut fiber

Twaron® short-cut fibers, available in lengths from 0.25 mm to 12 mm, enhance strength and stability in engineering plastics and composite materials. Processed into dipped, chopped fibers, they meet a variety of technical requirements.

Twaron® powder

Twaron® powder, defined by particle size, improves performance in engineering plastics, coatings, and rubber compounds. Its fine dispersion supports enhanced durability and thermal stability in specialized applications.

Twaron® pulp

Twaron® pulp strengthens friction materials, sealing solutions, and specialty papers. Available in wet or dry forms with adjustable fibril lengths and surface areas, it delivers reliable adhesion and reinforcement under demanding conditions.

How is Twaron® produced, certified, recycled?

Frequently asked questions

Find quick answers to common questions about our Twaron® aramid products. If you need more help, our team of experts is here for you.

Can Twaron® be recycled?

Yes, Twaron® supports a circular production process designed to maximize recycling and resource efficiency.

In 2023, the retrieval of pre- and post-consumer aramid waste increased by 24% compared to 2022, and we continue to invest in mechanical and chemical recycling technologies to extend material lifespan. Learn more in our Twaron® supports a circular production process focused on recycling and resource efficiency.

Learn more in our Sustainability Report.

What is the carbon footprint of Twaron®?

Since 2014, the carbon footprint of Twaron® has improved by 28%, with a 46% reduction in CO₂ Scope 1 and 2 emissions compared to 2020.

Our operations have also led to 313,000 tons of avoided CO₂ emissions across the value chain. We remain committed to further reducing emissions through energy efficiency and sustainable production.

More details can be found in the Sustainability Report.

Where is Twaron® made?

Twaron® is produced in the Netherlands, with production sites in Delfzijl and Emmen.

In Delfzijl, key monomers are synthesized and processed, while Emmen houses the world’s largest aramid factory, where Twaron® is spun and customized for different applications. Our Dutch facilities operate on 100% renewable electricity from solar and wind sources. Learn more in our Sustainability Report

What certifications does Twaron® have?

Twaron® meets international standards for quality, safety, and environmental management. We hold:

- ISO 9001: Quality Management

- ISO 14001: Environmental Management

- ISO 45001: Occupational Health & Safety

- AEO Certification: Authorized Economic Operator

We have also received an EcoVadis Gold Medal, ranking in the top 5% of all companies globally for sustainability and in the top 3% of fiber manufacturers. A full list of certifications is available in our resource library.

Get in touch with our aramid experts

Do you have technical questions about our aramid solutions, specifications, or applications? Fill out the contact form to speak directly with our material experts. We’re ready to provide detailed insights and discuss how our solutions can meet your specific needs.