Industry value

Supporting the transition to renewable energy

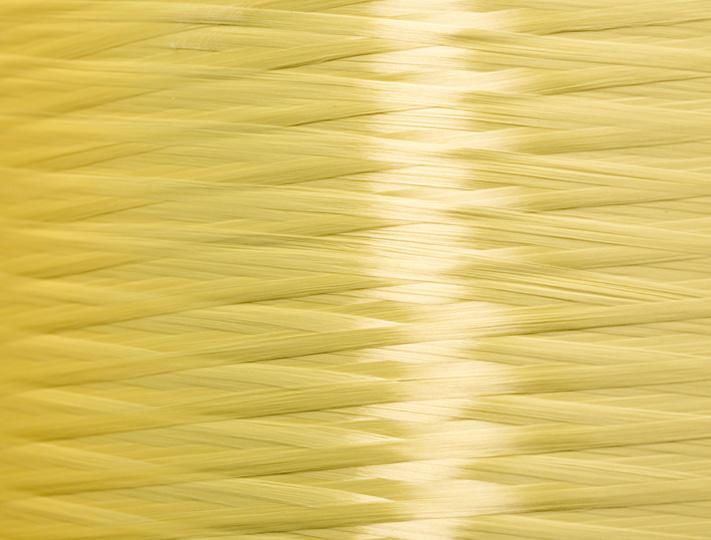

We empower you to tackle renewable energy projects in the most extreme conditions. Our lightweight aramid materials aren't just strong: designed for easy installation, they’re low maintenance and ready for deep-sea action that significantly lowers your carbon footprint compared to steel.

Sustainability

Securing a sustainable future

Easily recycled at the end of life, our aramid supports your transition to a circular economy. This not only reduces your carbon footprint, securing a more sustainable future for the renewable energy sector, but also contributes to the cleanliness of our seas and oceans.

One of our innovative projects repurposes used Twaron® yarn, spinning it into fresh strands without any loss in performance.

Solutions

A trusted partner in renewable energy solutions

Leveraging our deep industry knowledge and expansive network of established partnerships, we offer a range of possibilities for applications across floating wind farms, hydrogen transportation, carbon capture solutions, deep-sea installations and more.

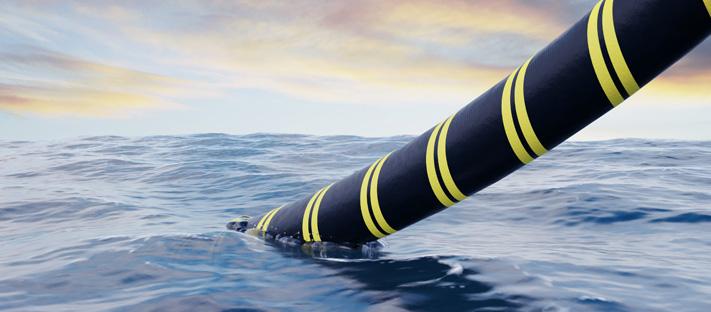

Submarine power cables

High-voltage submarine power cables are engineered to transmit electric power reliably across long distances beneath the ocean. Reinforcing these cables with aramid fibers like Twaron® combines lightweight strength with exceptional durability, making them ideal for deep-sea installations.

Permanent mooring

Stable floating wind platforms require strong, rigid and long-lasting materials. Mooring tendons made from Twaron® provide these qualities, with resistance to creep failure and high resistance to breaking.

This, and their low maintenance needs, make them an ideal choice for deep-sea operations and tension-focused mooring.

Reinforced thermoplastic pipes

Aramid-reinforced thermoplastic pipes (RTPs), with their excellent chemical and corrosion resistance, are crucial for future hydrogen infrastructure.

Twaron®-based RTPs not only make hydrogen gas transport safer but do so with a lifetime environmental impact three times lower than steel pipes, cementing them as the sustainable choice for the energy transition.

Our aramids

The premium para-aramid. It’s six times as strong as steel, with great heat and chemical resistance, ideal for industrial and reinforcement applications.

“The synergy between FibreMax and Teijin Aramid is strong. By producing our cables with Twaron®, we can develop cables with the exact length, strength, and stiffness to keep floating offshore wind turbines in place. Together with Teijin Aramid, we are building a greener future.”

Sander van Helvoort, Director Renewable Energy, FibreMax BV

Renewable energy experts

Updates

New and upcoming

We regularly attend renewable energy events and publish news and stories about our innovative work with industry partners.

Get in touch

Let’s share ideas and expertise

We are always interested in hearing about your ambitions, whether they are about installing offshore wind farms or powering the world. We’re here to help get you there.