Industry value

High-performance materials – the answer to lightweight mobility

As the automotive industry accelerates towards electrification and autonomous vehicles, our high-performance aramids offer lighter weight, durable and sustainable solutions for the next generation of electric vehicles.

Sustainability

Realizing a circular economy

As the automotive and tire industries navigate the shift to electric vehicles (EVs), our shared goals are clear: net zero emissions and full material circularity by 2050. EVs play a crucial role in this journey, and so do components made from our aramids, which decreases use-phase carbon footprint and increase battery range in EVs.

● Lower weight with the same performance

● Less fuel use and less CO2 emissions per kilometer

Solutions

Solutions for lightweight mobility

Electric vehicles, driverless cars and other innovative technologies demand fresh thinking for sustainable mobility. We need lighter, stronger, more durable vehicles. This is where our aramids play a key role.

Tire reinforcement

Twaron® has remarkable heat-resistant properties and unique strength, contributing to lighter, stronger, more sustainable tires.

● High strength, lower weight

● Improved high-speed performance

● Lower rolling resistance: less fuel, fewer emissions

● Excellent tire shape uniformity

Brake reinforcement

High-performance Twaron® para-aramid pulp enhances brake system performance and reduces brake dust emissions. Additionally, our product optimizes production efficiency.

● Less brake dust emissions compared to metallic solutions

● Easy processability

● Good wear performance

Hose reinforcement

Our aramids Twaron®, Technora® and Teijinconex® have outstanding reinforcement properties with exceptional resistance to thermal, dynamic and chemical damage. Aramid-reinforced hoses are stronger and last longer, making them especially suitable for maintenance-free electric vehicles (EVs).

● Heat resistant up to 250℃ (Teijinconex)

● High chemical resistance (fuel, cooling liquids, and more)

● Decreased leaking and tearing

● Retains durability and shape under high pressure and temperature

Our aramids

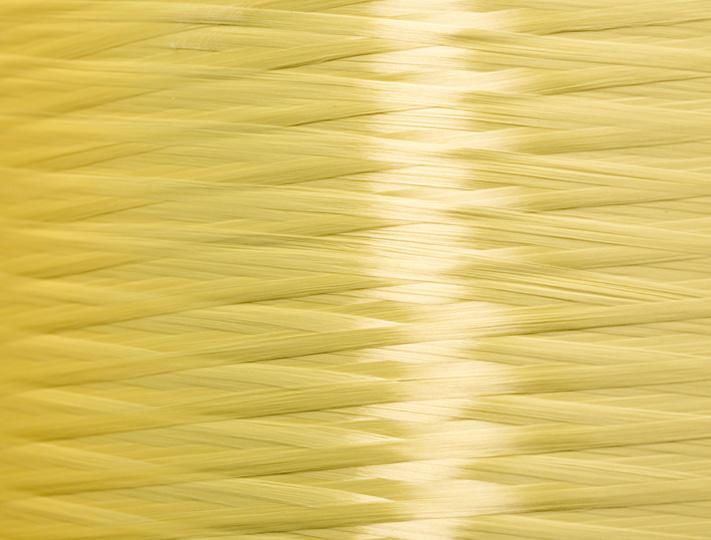

The premium para-aramid. It’s six times as strong as steel, with great heat and chemical resistance, ideal for industrial and reinforcement applications.

"At Beaver we believe that success is engineered. For more than 30 years we have been happy to call Teijin Aramid our partner on state of the art aramid solutions that meet, and surpass, the expectations of our customers. We continue to innovate together to this day."

Michael Dubin, President & CEO, Beaver Manufacturing Company, Inc

Automotive expert

Updates

New and upcoming

As partners in the rapidly evolving automotive sector, Teijin Aramid actively participates in numerous events and trade shows. Discover more about these, along with updates on our work in this dynamic industry, here.

Get in touch

Let’s share ideas and expertise

Interested in exploring sustainable mobility with us? Contact us if you have ideas and projects to share, need information, or if you are interested in a career at Teijin Aramid. We’ll have the right expert get in touch.